How rubber foam strips have a shock-absorbing effect

Release Date:2024-01-20 Click:4604

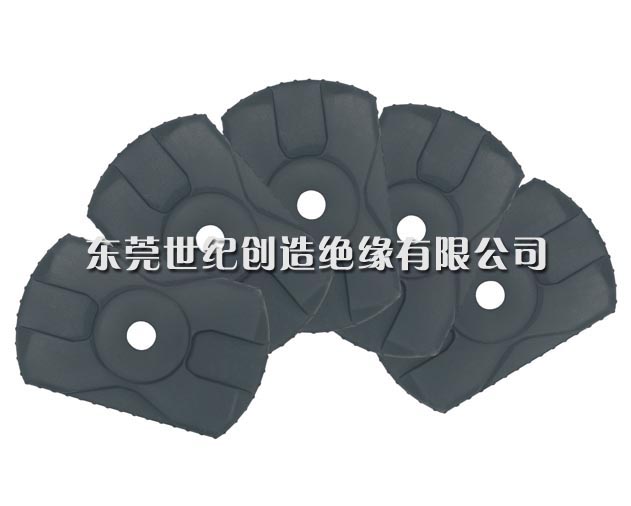

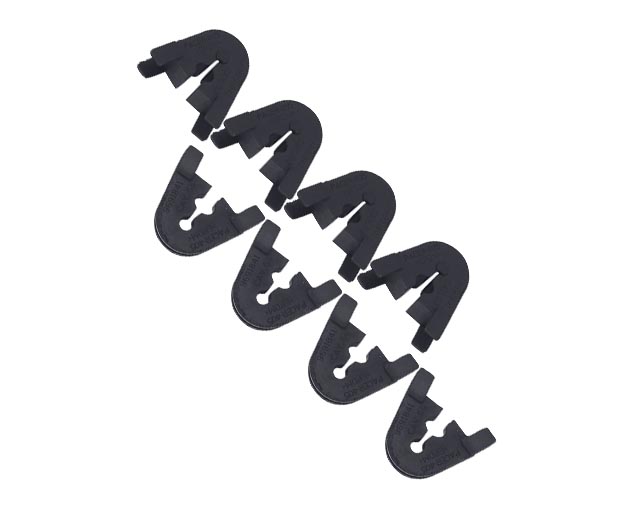

Next, let's talk about how rubber foam strips have a good shock absorption effect. Using benzyl alcohol perchloride as the initiator, acrylonitrile was grafted onto ethylene propylene rubber at 80 ℃. Acrylonitrile modified ethylene propylene rubber not only retains the corrosion resistance of ethylene propylene rubber, but also achieves oil resistance equivalent to -26, with good physical and mechanical properties, shock absorption, and processing performance. Thermoplastic ethylene propylene rubber (EPDM/PP) is a mixture of EPDM rubber foam strips and polypropylene. The product that simultaneously achieves the expected degree of crosslinking of ethylene propylene rubber. Hua not only retains the inherent characteristics of ethylene propylene rubber in terms of performance, but also has significant process performance in injection, extrusion, blow molding, and rolling molding of thermoplastic materials. Besides that.

However, due to the decrease in mechanical strength, brominated ethylene propylene rubber is only suitable as an intermediate layer for bonding ethylene propylene rubber with other rubbers. Chlorinated ethylene propylene rubber is made by passing chlorine gas through a solution of EPDM rubber foam strips. Chlorination of ethylene propylene rubber can improve the vulcanization rate, compatibility with unsaturated materials, flame resistance, oil resistance, and adhesive properties. Sulfonated ethylene propylene rubber is made by dissolving EPDM rubber foam strips in a solvent and treating them with sulfonating agents and neutralizing agents. Sulfonated ethylene propylene rubber, due to its thermoplastic elastomer and good adhesion performance, is used in adhesives, coated fabrics, and building waterproofing.

This provides numerous varieties and grades for the widespread application of ethylene propylene rubber. Modified ethylene propylene rubber mainly involves bromination, chlorination, sulfonation, maleic anhydride, organic silicon modification, nylon modification, etc. Ethylene propylene rubber also has grafted acrylonitrile, acrylic ester, etc. Over the years, many high-performance polymer materials have been obtained through methods such as blending, copolymerization, filling, grafting, reinforcement, and molecular composite. Through modification, ethylene propylene rubber has also achieved significant improvements in performance, providing good shock absorption and elasticity benefits to the components of machinery and equipment. Therefore, it provides good protection for the mechanical equipment we produce, thereby expanding the application range of ethylene propylene rubber. Brominated ethylene propylene rubber is processed by brominating agents on the open mill.

Next article:Selection of Rubber Raw Materials for Rubber Sponge Products

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization